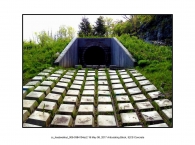

Articulating Concrete Block

International Erosion Control Systems has been manufacturing and marketing soil stabilization and erosion control products since 1984. IECS has become one of the leading international companies for solving soil erosion problems.

I.E.C.S. specializes in Cable Concrete®, one of the most advanced engineering technologies available.

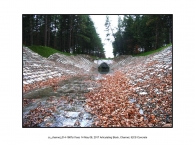

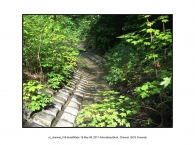

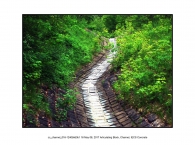

Cable Concrete® is an Articulating Concrete Block (ACB) system connected by cables allowing each individual block to be flexible and intimately form to the terrain.

This interconnected block system is available in four different thicknesses to provide the economically required stability for each.

Cable Concrete® has been extensively testing by engineering departments at three different universities: The University of Windsor, Ontario; The University of Colorado; and The University of Minnesota.

Complete engineering analysis, with flume testing, has been conducted by the Department of Civil and Environmental Engineering, University of Windsor, Ontario, Canada, University of Colorado and the University of Minnesota.

Cable Concrete® is manufactured to exact specifications, which exceed both federal, provincial MTO and state D.O.T. requirements

Facts-Stability

The integrated cable in Cable Concrete® allows for interlocking of all mats to form a single strong unit to cover any area required. Clamping is recommended for high flow and steep slope applications.

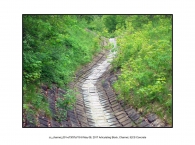

Facts-Flexibility

The design is key in providing maximum effectiveness based on engineering principles. In order to provide maximum effectiveness, erosion control, the protective application must keep a uniform pressure on the geotextile and subgrade material at all times.

Facts-Versatility

Cable Concrete® can easily be cut to fit smaller areas, irregular shapes, and allow for drainage pipes, manholes, and other obstructions.

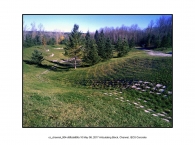

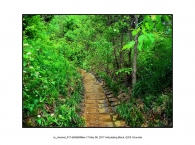

Fact-Vegetative Growth

The large percentage of open area within the Cable Concrete® system, offers extensive vegetation opportunities.

Facts-Anchoring

A key feature of integrated cable is the extra stability it offers through the use of earth anchors and/or tow-in options.

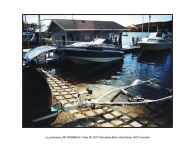

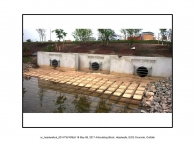

Facts-Vehicle Access

Integrated cable allows external forces to distribute the load throughout the mat system. Creek crossings and river beds are easily constructed. Maintenance vehicles can easily maneuver over this steady surface.

Facts-Installation

Cable Concrete® is exceptionally easy to install above and below water level. On-site assembly is not required; therefore keeping labor to a minimum.

Facts-Benefits

- It is a cost-effective solution to severe or minor erosion problems.

- Precast mats with preattached geotextile speed installation and quality of the finished project.

- Easily maintained when vegetated or rock filled.

- They are highly resistant to ice damage and freeze-thaw cycles.

- They allow safe access.

- Flexible mats can conform to existing ground contours. They minimize site preparation.

- Mats can be removed and reused on future sites.

- Local precasters manufacture Cable Concrete® to exacting specifications, which exceed both federal, provincial MTO and state D.O.T. material requirements assuring a quality product.